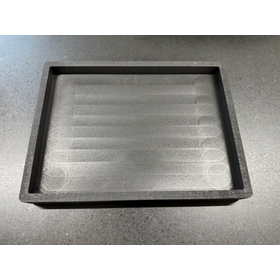

Trays for high-temperature furnaces and vacuum furnaces for metal heat treatment.

Optimize the quenching process with carbon graphite trays.

In the metal heat treatment industry, particularly in the quenching process, trays that can withstand high temperatures and enable uniform heat treatment are required. The material and shape of the trays are crucial factors that influence product quality. Carbon-graphite trays excel in thermal conductivity and heat resistance, contributing to the improvement of product quality in the quenching process. Our products can be customized to meet customer needs. 【Usage Scenarios】 - Transporting products during the quenching process - Holding products in high-temperature environments - Use in vacuum furnaces 【Benefits of Implementation】 - Achieving uniform heat treatment - Improving product quality - Extending the lifespan of trays

- Company:東京炭素工業

- Price:Other